Chemical Etching Technology for EMI/RFI Shielding Covers

In today’s electronics-driven world, where devices operate at ever-higher speeds and frequencies, electromagnetic interference (EMI) and radio frequency interference (RFI) pose significant challenges to performance and reliability. To mitigate these unwanted electromagnetic effects, engineers rely on EMI/RFI shielding covers — precision metal enclosures designed to block or contain electromagnetic radiation.

As product designs become smaller, lighter, and more complex, the demand for thin, lightweight, and precisely formed shielding components has surged. Among the various manufacturing methods available, chemical etching (also known as photochemical machining) stands out as the most advanced and versatile technology for producing high-precision EMI/RFI shields.

The Role of EMI/RFI Shielding Covers

EMI/RFI shielding covers are thin metal components used to enclose or isolate sensitive circuits, preventing unwanted interference between nearby components or external sources. They are commonly used in smartphones, communication devices, automotive electronics, medical instruments, and aerospace systems.

A typical shielding cover must combine electrical conductivity, mechanical precision, and dimensional consistency. It often includes small ventilation holes, contact tabs, grounding features, and snap-fit structures — all requiring micron-level accuracy. These requirements make chemical etching the ideal manufacturing method.

Chemical Etching Technology for Precision Electrodes and Contact Sheets

In high-performance electronic and electrical systems, precision electrodes and contact sheets play a critical role in ensuring stable conductivity, accurate signal transmission, and long-term durability. These components are widely used in batteries, sensors, medical instruments, automotive connectors, and communication devices — all of which demand exceptional dimensional precision and surface integrity.

Traditional manufacturing techniques such as stamping, wire cutting, or laser machining often struggle to achieve the fine geometries, stress-free edges, and material consistency required for today’s miniaturized designs. To meet these challenges, manufacturers increasingly rely on chemical etching technology, also known as photochemical machining (PCM) — a process that combines photolithography and controlled chemical dissolution to create ultra-precise metal parts without mechanical stress.

The Role of Precision Electrodes and Contact Sheets

Electrodes and contact sheets serve as conductive interfaces that enable electrical current to flow efficiently between components. In applications such as lithium-ion batteries, fuel cells, and sensors, electrodes must feature high conductivity, corrosion resistance, and precise microstructures that control current density and chemical reactions.

In connectors and switching systems, contact sheets must maintain tight tolerances for both dimensional accuracy and surface finish to ensure consistent contact resistance and mechanical fit. As devices become smaller and more compact, the need for ultra-thin, high-density electrode patterns has made traditional fabrication methods increasingly inadequate.

Chemical etching provides a solution that combines micron-level precision, design flexibility, and excellent material preservation, making it ideal for producing the next generation of precision electrodes and contacts.

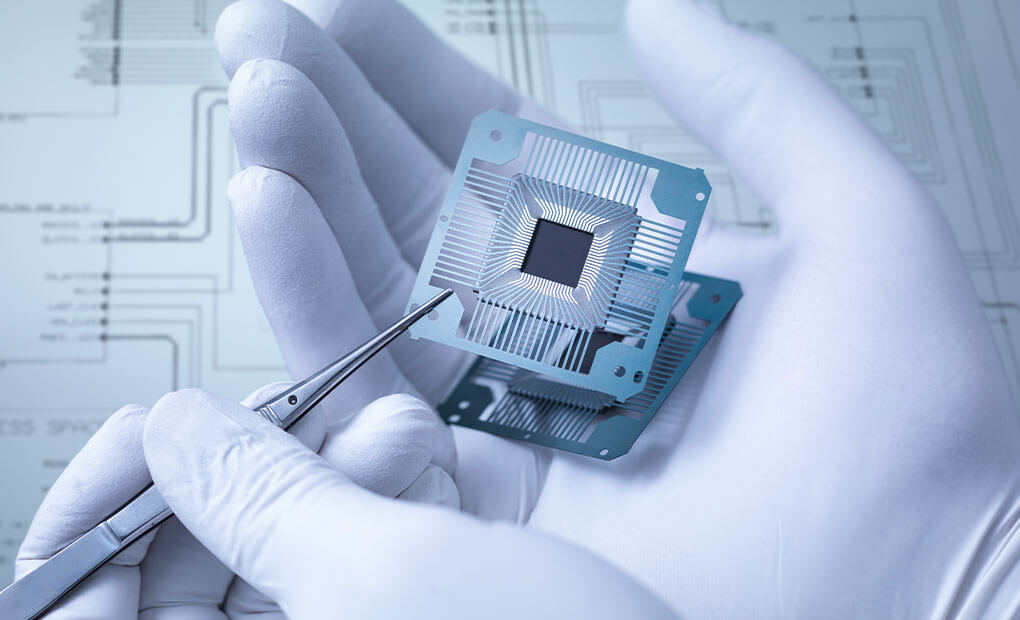

Chemical Etching Technology in Semiconductor Lead Frame Manufacturing

In the semiconductor industry, precision, reliability, and scalability define success. As electronic devices become smaller, faster, and more powerful, the demand for ultra-fine metal components with exacting tolerances continues to grow. Among these components, lead frames play a crucial role — they form the electrical connection between the semiconductor chip and the external circuitry of an integrated circuit (IC) package. To meet modern requirements for miniaturization and high performance, chemical etching has become one of the most advanced and efficient manufacturing methods for producing semiconductor lead frames.

1. The Role of Lead Frames in Semiconductor Packaging

A lead frame serves as both a mechanical support and an electrical pathway. It anchors the semiconductor die in place, conducts signals between the chip and the printed circuit board (PCB), and helps dissipate heat generated during operation. Traditionally, lead frames were produced by stamping or photolithographic electroplating, but as device geometries have shrunk and multi-layer packaging technologies have evolved, these conventional methods have reached their technical limits.

For modern ICs — such as QFP (Quad Flat Package), QFN (Quad Flat No-lead), BGA (Ball Grid Array), and advanced system-in-package (SiP) designs — dimensional precision, edge definition, and material consistency are critical. Even microscopic defects or burrs can affect electrical performance and bonding reliability. This is where chemical etching stands out.

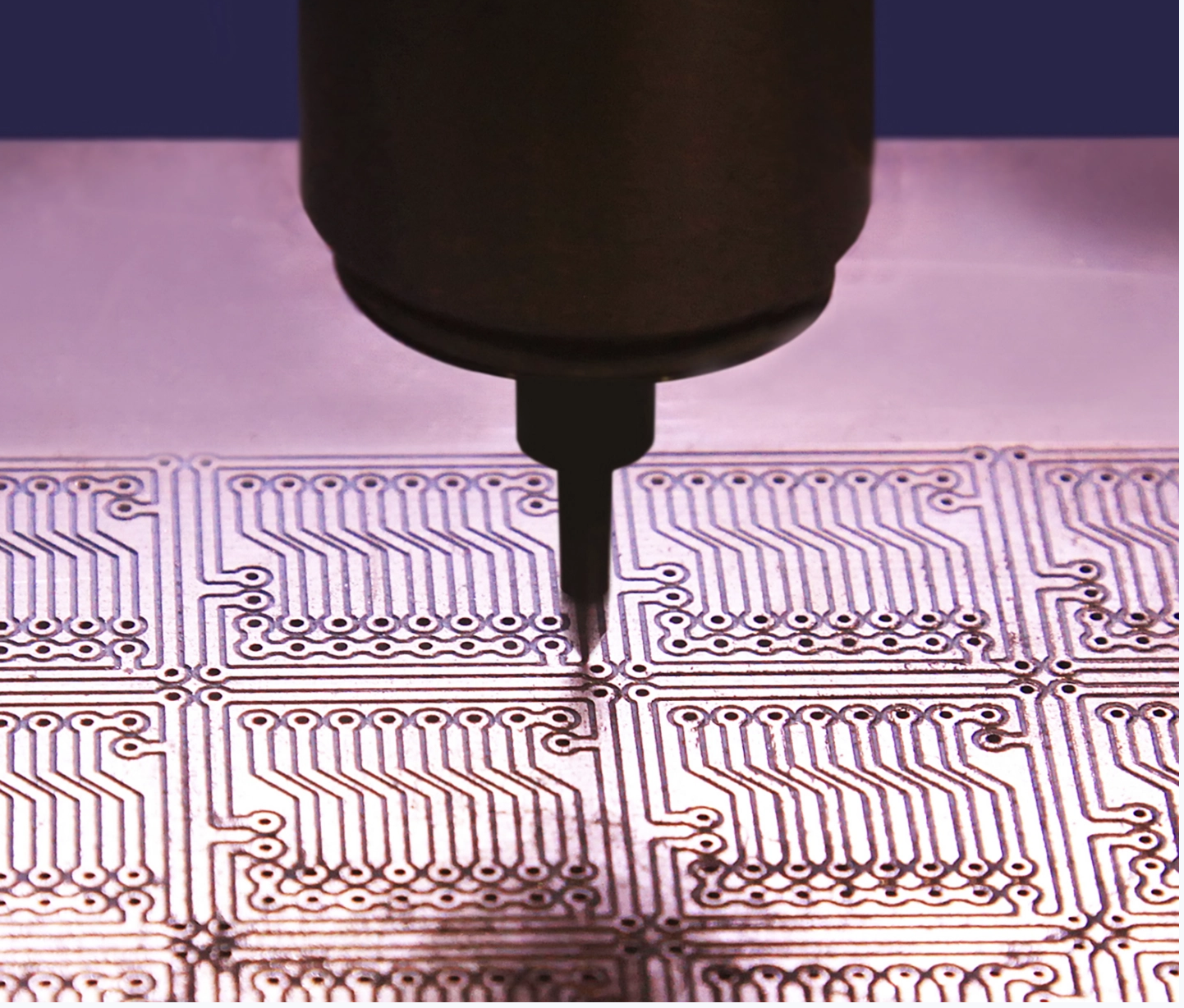

Chemical Etching Technology in PCB Inner Metal Layers

As the electronics industry continues to push the boundaries of performance, speed, and miniaturization, the printed circuit board (PCB) has evolved into a sophisticated, multi-layered structure. At the core of every multilayer PCB lie the inner metal layers — the conductive pathways that interconnect signals, distribute power, and ground critical components. Manufacturing these inner layers with precision and consistency is essential for ensuring the reliability and performance of the entire electronic system. Among the various fabrication techniques available, chemical etching has emerged as the most effective and accurate method for creating fine-featured inner metal patterns in modern PCB production.

The Role of Inner Metal Layers in PCB Manufacturing

A multilayer PCB is composed of alternating layers of conductive metal (typically copper) and insulating dielectric materials (such as FR-4 or polyimide). The inner metal layers form the signal traces, power planes, and ground networks that interconnect the electronic components mounted on the outer surfaces.

During PCB fabrication, these inner layers are created first and then laminated together with insulating prepreg layers to form the complete circuit board. Because they are embedded within the structure, the accuracy and integrity of the inner metal patterns are crucial — once laminated, they cannot be inspected or repaired. Even microscopic deviations in line width, spacing, or registration can cause impedance mismatches, signal loss, or electrical failure.

This is where chemical etching becomes indispensable. It offers the precision, repeatability, and clean surface definition required to form ultra-fine circuitry inside multilayer PCBs.

Chemical Etching in Medical & Consumer Electronics Applications

Chemical etching, also known as photochemical or wet etching, is a precise metal fabrication process that removes material from metal surfaces through controlled chemical reactions. Its ability to produce highly accurate, intricate designs makes it a critical technology across multiple industries, particularly in medical devices and consumer electronics.

1. Medical Applications

In the medical field, chemical etching is widely used for producing components that require exceptional precision and biocompatibility. Typical applications include:

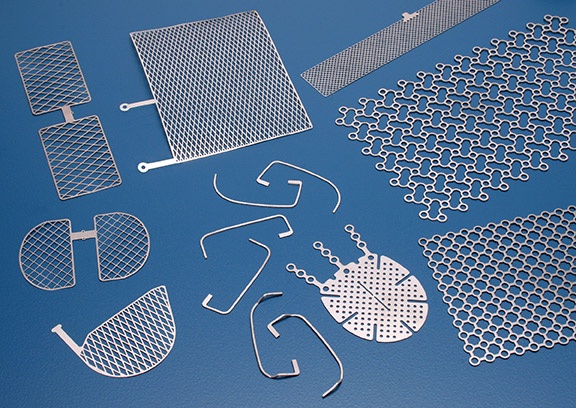

Surgical Instruments: Fine blades, micro-scissors, and other precision instruments are etched to achieve sharp edges and exact geometries.

Implants and Stents: Chemical etching allows the creation of complex patterns on stents or implants, optimizing flexibility, surface area, and blood flow.

Microfluidic Devices: These devices, used for lab-on-a-chip applications, rely on etched metal or polymer channels for fluid control and analysis.

Advantages of chemical etching in medical applications include minimal mechanical stress during fabrication, high repeatability, and the ability to work with biocompatible metals such as stainless steel, titanium, and nickel alloys.

2. Consumer Electronics Applications

In consumer electronics, miniaturization and precision are key. Chemical etching is used to produce high-precision metal components that are essential in:

Printed Circuit Boards (PCBs): Etching is critical for defining conductive pathways with fine resolution on copper layers.

Micro Connectors and Contacts: Tiny metallic contacts in smartphones, tablets, and wearable devices are chemically etched to ensure reliable electrical connections.

Decorative and Functional Metal Parts: Metal buttons, speaker grills, and heat sinks can be etched for both aesthetic and functional purposes, including weight reduction and heat dissipation.

Chemical etching offers electronics manufacturers the ability to produce components with extremely fine detail, complex geometries, and smooth finishes, which are often impossible to achieve through traditional mechanical methods.

In Conclusion

Chemical etching has become an indispensable technology in the medical and consumer electronics sectors. Its precision, versatility, and ability to handle intricate designs make it ideal for applications where quality and reliability are paramount. As both industries continue to demand smaller, lighter, and more complex components, the role of chemical etching is only set to expand, providing efficient and high-quality solutions for modern manufacturing challenges.

Advanced Metal Etching for the Automotive Industry: Engineering Precision for Next-Generation Vehicle Systems

As vehicle platforms evolve toward electrification, autonomy, and higher system integration, the automotive industry increasingly relies on fabrication processes capable of producing high-accuracy, lightweight, and thermally efficient metal components. Photo Chemical Etching (PCE)—also known as chemical machining—has emerged as a critical manufacturing method due to its ability to produce micron-level precision in thin-gauge metals without inducing mechanical or thermal stress.

This article examines the engineering principles, process capabilities, and technical applications of metal etching within modern automotive systems.

The Application of Chemical Etching in Automotive and Industrial Sectors

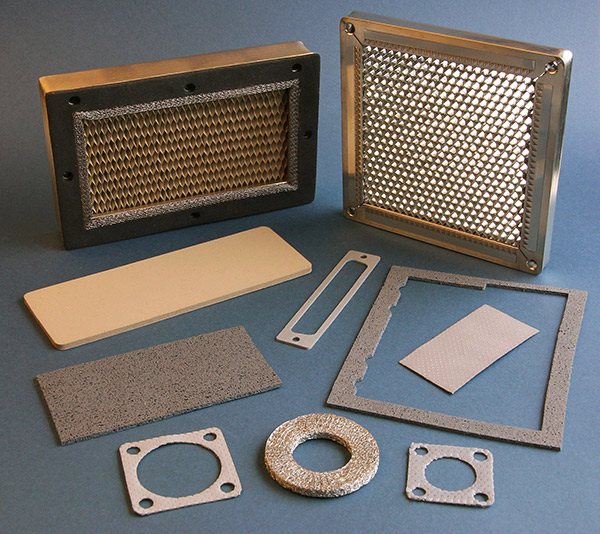

Chemical etching is widely used in the automotive and industrial sectors to manufacture precision metal components that demand high accuracy, durability, and cost efficiency. Unlike traditional stamping or machining, photochemical etching allows for the creation of intricate designs and fine details without introducing mechanical stress or deformation, making it especially valuable for modern engineering applications.

In the automotive industry, etched components are applied in fuel injection systems, heat exchangers, gaskets, precision shims, and EMI/RFI shielding for electronic control units. These parts contribute to improved engine performance, thermal management, and vehicle reliability. Lightweight metals such as aluminum and stainless steel are often etched to meet the industry’s increasing demand for weight reduction and energy efficiency.

In industrial applications, etched parts include filtration plates, motor laminations, cooling elements, and specialized washers or spacers. The process ensures repeatability, tight tolerances, and burr-free finishes, which are critical for large-scale machinery and high-performance equipment.

By offering flexibility in design, reduced tooling costs, and rapid prototyping capabilities, chemical etching continues to support innovation in both automotive and industrial fields, helping manufacturers meet the challenges of precision, efficiency, and sustainability.

The Application of Chemical Etching in Optical and Filtration Industries

Chemical etching provides advanced solutions for both the optical and filtration industries, where high precision, fine detail, and consistent performance are critical. Using photochemical techniques, metals can be processed into extremely thin, complex, and burr-free components that traditional machining cannot achieve.

In the optical field, chemical etching is widely applied to create precision apertures, masks, diaphragms, and alignment components used in cameras, sensors, and laser systems. The process allows for micron-level accuracy and smooth edge quality, ensuring minimal light distortion and superior optical performance.

In the filtration industry, etched metal meshes, screens, and perforated plates are commonly produced from stainless steel, nickel alloys, and other durable materials. These components feature consistent pore sizes, uniform geometry, and reliable flow characteristics, making them ideal for applications in medical devices, automotive systems, chemical processing, and environmental technologies.

Compared to stamping or punching, chemical etching minimizes tool wear and eliminates distortion, enabling the creation of intricate and highly repeatable designs. This makes it an essential manufacturing method for optical precision and high-performance filtration solutions across diverse industries.

The Role of Chemical Etching in Cultural and Custom Gifts

Chemical etching offers unique opportunities in the creation of cultural and custom gift products by combining precision manufacturing with artistic expression. This process allows for intricate patterns, fine details, and customized designs to be permanently engraved or cut into metal surfaces, making it highly suitable for decorative and commemorative items.

From traditional cultural symbols and architectural motifs to modern logos and personalized messages, chemical etching provides unmatched flexibility for both small-scale and mass production. Materials such as stainless steel, brass, copper, and precious metals can be processed into bookmarks, ornaments, keychains, plaques, and luxury packaging accessories. The resulting products are not only durable and elegant but also retain the authenticity of cultural identity and craftsmanship.

Compared to conventional engraving or stamping, photochemical etching ensures cleaner lines, sharper details, and greater design freedom. This enables manufacturers and designers to deliver truly bespoke cultural gifts that carry both emotional and aesthetic value, perfectly suited for souvenirs, corporate gifts, and creative industries.