Chemical Etching Technology for EMI/RFI Shielding Covers

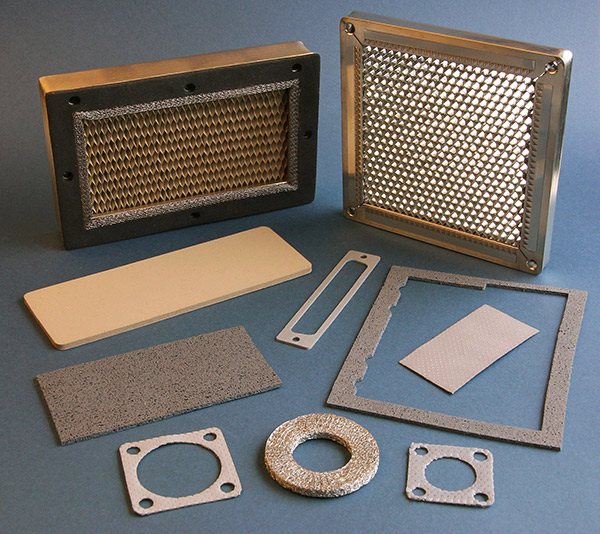

In today’s electronics-driven world, where devices operate at ever-higher speeds and frequencies, electromagnetic interference (EMI) and radio frequency interference (RFI) pose significant challenges to performance and reliability. To mitigate these unwanted electromagnetic effects, engineers rely on EMI/RFI shielding covers — precision metal enclosures designed to block or contain electromagnetic radiation.

As product designs become smaller, lighter, and more complex, the demand for thin, lightweight, and precisely formed shielding components has surged. Among the various manufacturing methods available, chemical etching (also known as photochemical machining) stands out as the most advanced and versatile technology for producing high-precision EMI/RFI shields.

The Role of EMI/RFI Shielding Covers

EMI/RFI shielding covers are thin metal components used to enclose or isolate sensitive circuits, preventing unwanted interference between nearby components or external sources. They are commonly used in smartphones, communication devices, automotive electronics, medical instruments, and aerospace systems.

A typical shielding cover must combine electrical conductivity, mechanical precision, and dimensional consistency. It often includes small ventilation holes, contact tabs, grounding features, and snap-fit structures — all requiring micron-level accuracy. These requirements make chemical etching the ideal manufacturing method.

Chemical Etching Technology for Precision Electrodes and Contact Sheets

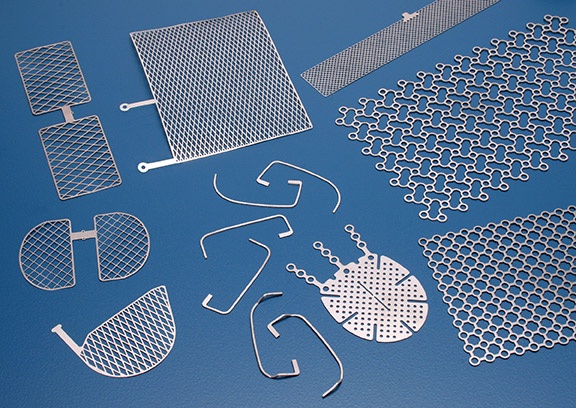

In high-performance electronic and electrical systems, precision electrodes and contact sheets play a critical role in ensuring stable conductivity, accurate signal transmission, and long-term durability. These components are widely used in batteries, sensors, medical instruments, automotive connectors, and communication devices — all of which demand exceptional dimensional precision and surface integrity.

Traditional manufacturing techniques such as stamping, wire cutting, or laser machining often struggle to achieve the fine geometries, stress-free edges, and material consistency required for today’s miniaturized designs. To meet these challenges, manufacturers increasingly rely on chemical etching technology, also known as photochemical machining (PCM) — a process that combines photolithography and controlled chemical dissolution to create ultra-precise metal parts without mechanical stress.

The Role of Precision Electrodes and Contact Sheets

Electrodes and contact sheets serve as conductive interfaces that enable electrical current to flow efficiently between components. In applications such as lithium-ion batteries, fuel cells, and sensors, electrodes must feature high conductivity, corrosion resistance, and precise microstructures that control current density and chemical reactions.

In connectors and switching systems, contact sheets must maintain tight tolerances for both dimensional accuracy and surface finish to ensure consistent contact resistance and mechanical fit. As devices become smaller and more compact, the need for ultra-thin, high-density electrode patterns has made traditional fabrication methods increasingly inadequate.

Chemical etching provides a solution that combines micron-level precision, design flexibility, and excellent material preservation, making it ideal for producing the next generation of precision electrodes and contacts.

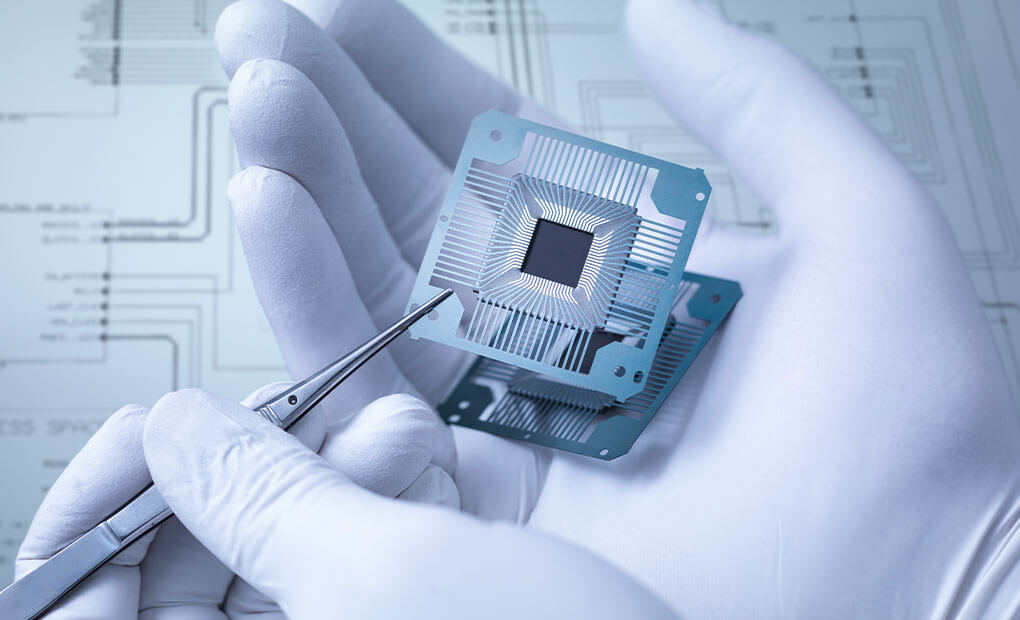

Chemical Etching Technology in Semiconductor Lead Frame Manufacturing

In the semiconductor industry, precision, reliability, and scalability define success. As electronic devices become smaller, faster, and more powerful, the demand for ultra-fine metal components with exacting tolerances continues to grow. Among these components, lead frames play a crucial role — they form the electrical connection between the semiconductor chip and the external circuitry of an integrated circuit (IC) package. To meet modern requirements for miniaturization and high performance, chemical etching has become one of the most advanced and efficient manufacturing methods for producing semiconductor lead frames.

1. The Role of Lead Frames in Semiconductor Packaging

A lead frame serves as both a mechanical support and an electrical pathway. It anchors the semiconductor die in place, conducts signals between the chip and the printed circuit board (PCB), and helps dissipate heat generated during operation. Traditionally, lead frames were produced by stamping or photolithographic electroplating, but as device geometries have shrunk and multi-layer packaging technologies have evolved, these conventional methods have reached their technical limits.

For modern ICs — such as QFP (Quad Flat Package), QFN (Quad Flat No-lead), BGA (Ball Grid Array), and advanced system-in-package (SiP) designs — dimensional precision, edge definition, and material consistency are critical. Even microscopic defects or burrs can affect electrical performance and bonding reliability. This is where chemical etching stands out.

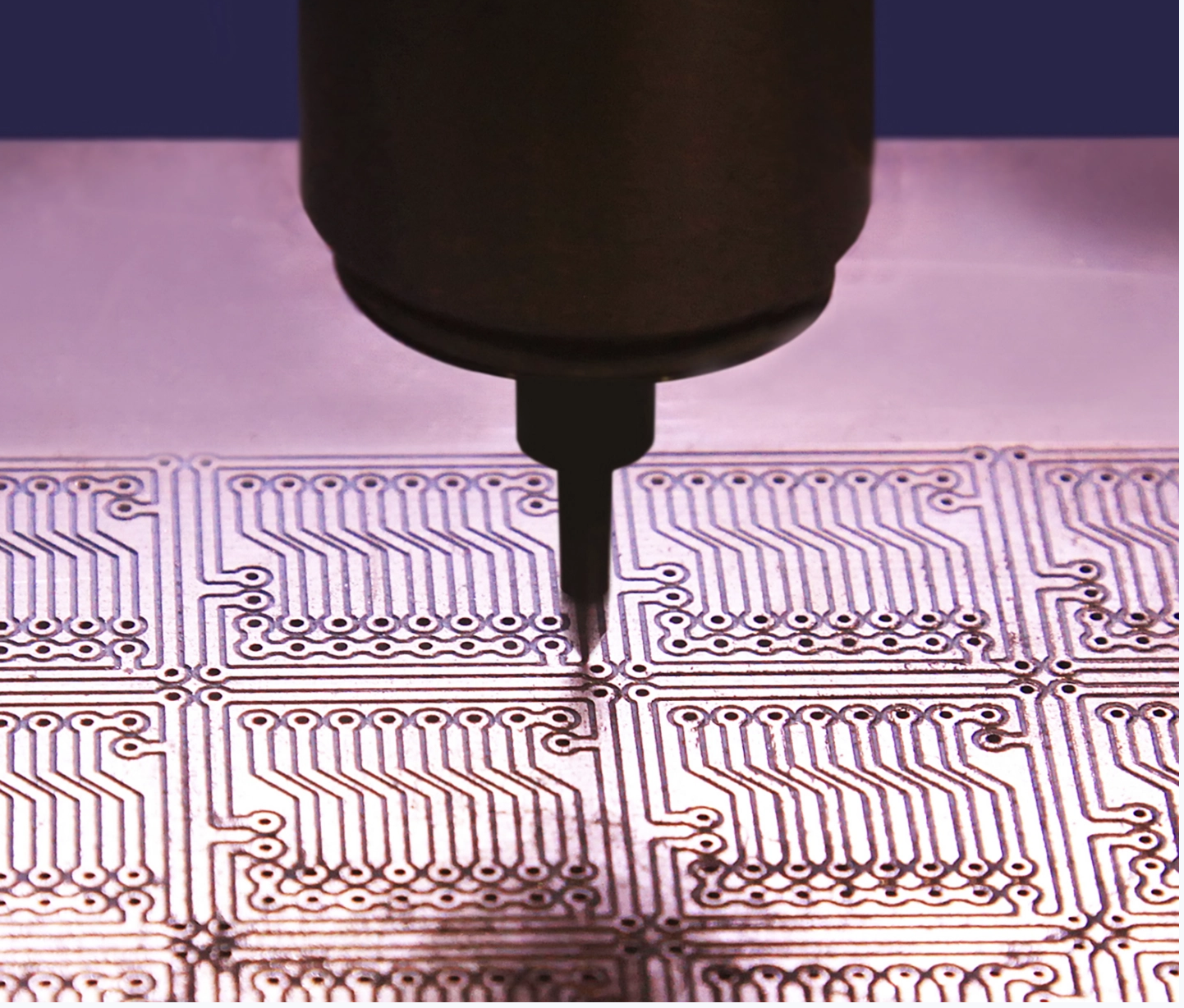

Chemical Etching Technology in PCB Inner Metal Layers

As the electronics industry continues to push the boundaries of performance, speed, and miniaturization, the printed circuit board (PCB) has evolved into a sophisticated, multi-layered structure. At the core of every multilayer PCB lie the inner metal layers — the conductive pathways that interconnect signals, distribute power, and ground critical components. Manufacturing these inner layers with precision and consistency is essential for ensuring the reliability and performance of the entire electronic system. Among the various fabrication techniques available, chemical etching has emerged as the most effective and accurate method for creating fine-featured inner metal patterns in modern PCB production.

The Role of Inner Metal Layers in PCB Manufacturing

A multilayer PCB is composed of alternating layers of conductive metal (typically copper) and insulating dielectric materials (such as FR-4 or polyimide). The inner metal layers form the signal traces, power planes, and ground networks that interconnect the electronic components mounted on the outer surfaces.

During PCB fabrication, these inner layers are created first and then laminated together with insulating prepreg layers to form the complete circuit board. Because they are embedded within the structure, the accuracy and integrity of the inner metal patterns are crucial — once laminated, they cannot be inspected or repaired. Even microscopic deviations in line width, spacing, or registration can cause impedance mismatches, signal loss, or electrical failure.

This is where chemical etching becomes indispensable. It offers the precision, repeatability, and clean surface definition required to form ultra-fine circuitry inside multilayer PCBs.