Chemical Etching Technology for EMI/RFI Shielding Covers

In today’s electronics-driven world, where devices operate at ever-higher speeds and frequencies, electromagnetic interference (EMI) and radio frequency interference (RFI) pose significant challenges to performance and reliability. To mitigate these unwanted electromagnetic effects, engineers rely on EMI/RFI shielding covers — precision metal enclosures designed to block or contain electromagnetic radiation.

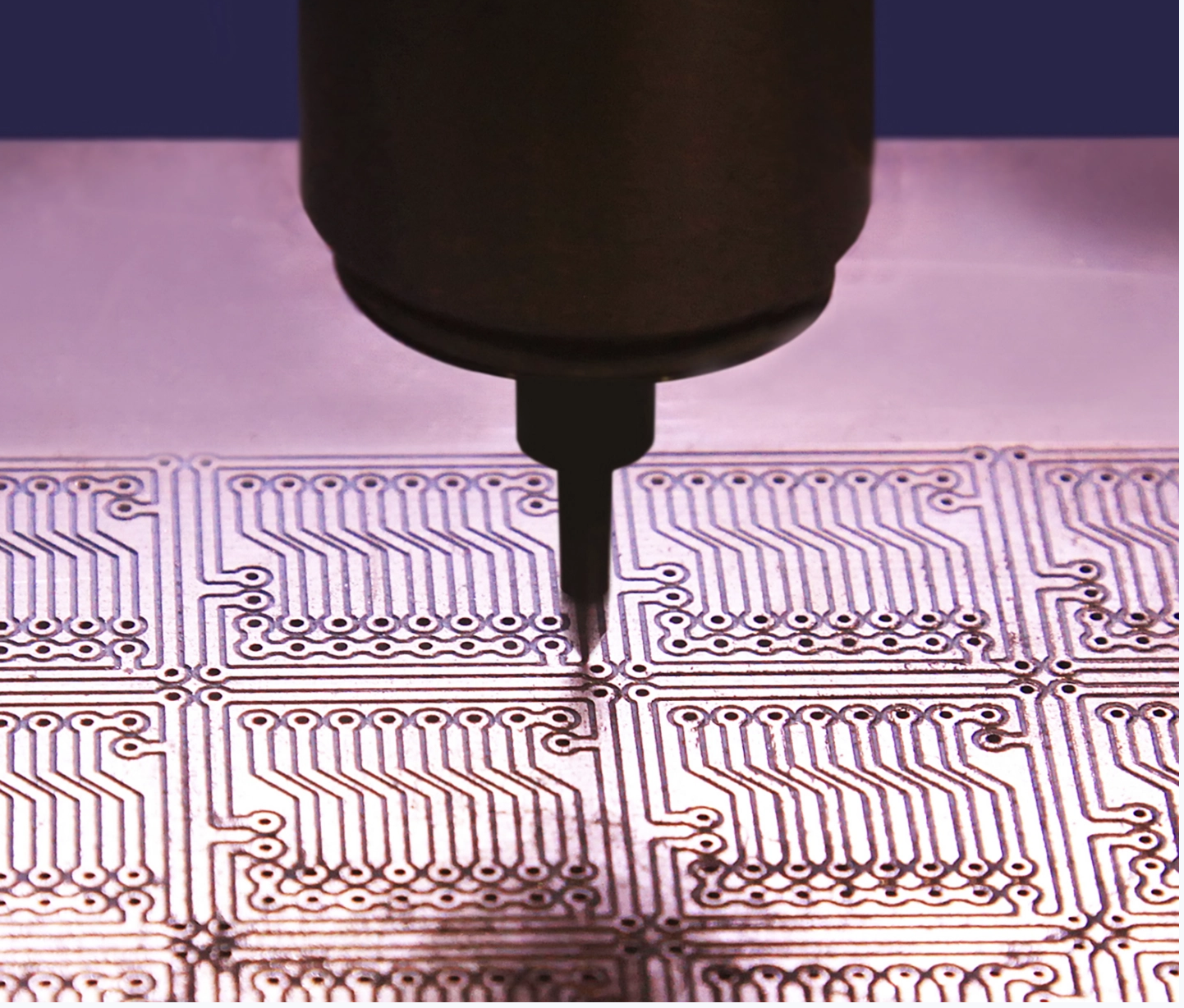

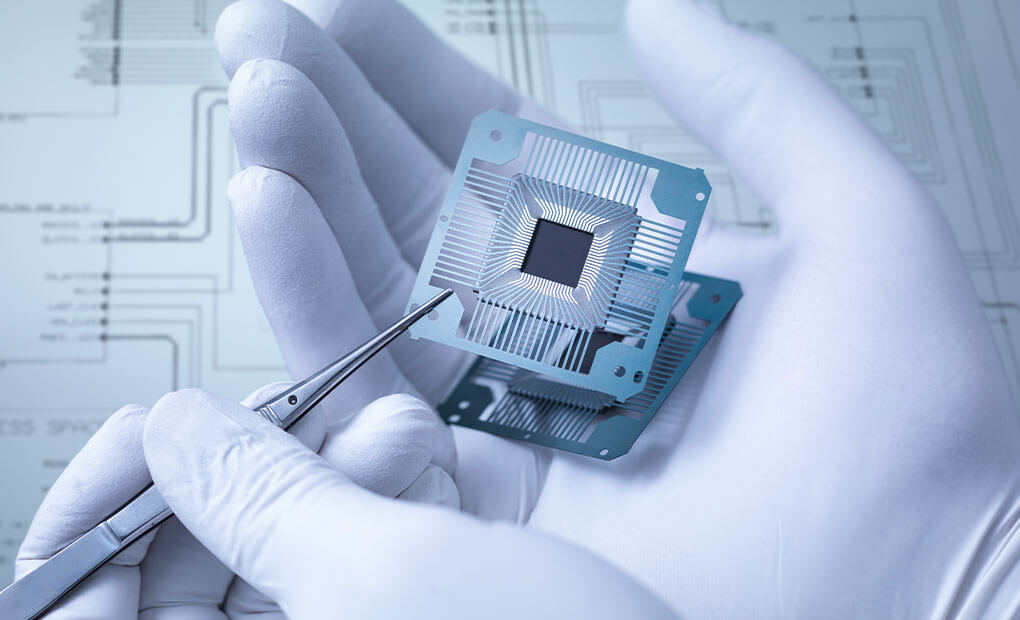

As product designs become smaller, lighter, and more complex, the demand for thin, lightweight, and precisely formed shielding components has surged. Among the various manufacturing methods available, chemical etching (also known as photochemical machining) stands out as the most advanced and versatile technology for producing high-precision EMI/RFI shields.

The Role of EMI/RFI Shielding Covers

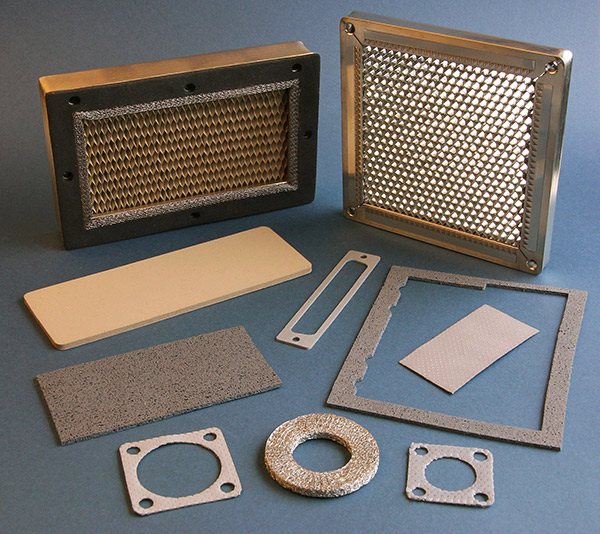

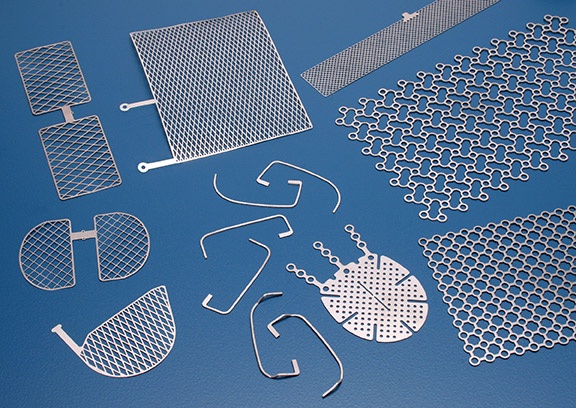

EMI/RFI shielding covers are thin metal components used to enclose or isolate sensitive circuits, preventing unwanted interference between nearby components or external sources. They are commonly used in smartphones, communication devices, automotive electronics, medical instruments, and aerospace systems.

A typical shielding cover must combine electrical conductivity, mechanical precision, and dimensional consistency. It often includes small ventilation holes, contact tabs, grounding features, and snap-fit structures — all requiring micron-level accuracy. These requirements make chemical etching the ideal manufacturing method.

Chemical Etching Technology for EMI/RFI Shielding Covers

In today’s electronics-driven world, where devices operate at ever-higher speeds and frequencies, electromagnetic interference (EMI) and radio frequency interference (RFI) pose significant challenges to performance and reliability. To mitigate these unwanted electromagnetic effects, engineers rely on EMI/RFI shielding covers — precision metal enclosures designed to block or contain electromagnetic radiation.

As product designs become smaller, lighter, and more complex, the demand for thin, lightweight, and precisely formed shielding components has surged. Among the various manufacturing methods available, chemical etching (also known as photochemical machining) stands out as the most advanced and versatile technology for producing high-precision EMI/RFI shields.

The Role of EMI/RFI Shielding Covers

EMI/RFI shielding covers are thin metal components used to enclose or isolate sensitive circuits, preventing unwanted interference between nearby components or external sources. They are commonly used in smartphones, communication devices, automotive electronics, medical instruments, and aerospace systems.

A typical shielding cover must combine electrical conductivity, mechanical precision, and dimensional consistency. It often includes small ventilation holes, contact tabs, grounding features, and snap-fit structures — all requiring micron-level accuracy. These requirements make chemical etching the ideal manufacturing method.