The Application of Iron Alloys in Chemical Etching

Iron alloys, including various grades of carbon steel and specialty steels, are widely applied in the chemical etching industry due to their strength, toughness, and cost-effectiveness. Through photochemical etching, iron-based materials can be manufactured into precise, complex geometries while avoiding the deformation or burrs typically caused by traditional machining methods. This makes them highly suitable for industrial, automotive, and engineering applications where both performance and precision are required.

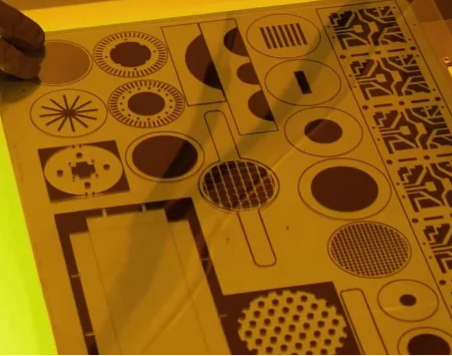

Etched iron alloy components are commonly used in gears, washers, precision shims, motor laminations, filtration plates, and structural parts. In automotive and mechanical industries, etched steel shims and spacers help achieve exact tolerances, ensuring reliable assembly and performance. In addition, surface treatments such as passivation, plating, or coating can be applied after etching to improve corrosion resistance and extend service life.

Compared with stamping or laser cutting, chemical etching provides cost-effective prototyping and mass production for iron alloys, enabling high repeatability, fine detail, and reduced tooling costs. As a result, iron alloys remain an essential category of materials in modern photochemical etching processes across multiple industries.