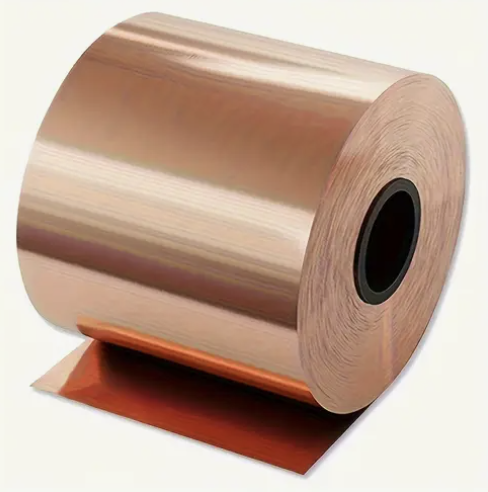

Brass, copper, and bronze are widely applied in the chemical etching industry due to their excellent conductivity, formability, and decorative qualities.

Brass, copper, and bronze are widely applied in the chemical etching industry due to their excellent conductivity, formability, and decorative qualities. Copper and its alloys are particularly suitable for applications that require high electrical and thermal conductivity, making them a preferred choice in electronics, telecommunications, and semiconductor components. Brass, with its good mechanical strength and corrosion resistance, is often etched into precision connectors, contact springs, and decorative metal elements. Bronze, valued for its durability and wear resistance, is commonly used in specialty filters, precision shims, and artistic or industrial design components.

Compared with mechanical machining, photochemical etching of these copper-based alloys allows for fine detail reproduction, burr-free edges, and consistent accuracy even in very thin foils. This process is ideal for producing micro-perforated meshes, shielding elements, intricate logos, and customized parts with complex geometries. In addition, the natural color variations of brass, copper, and bronze offer unique decorative possibilities in architectural and creative design fields.

By leveraging the advantages of chemical etching, these traditional alloys are continually being adapted for modern applications, combining both functionality and aesthetics across multiple industries.